poss@poss.com.eg

Fri & Sat CLOSED

Zahraa Maadi, Cairo, Egypt

Services & Solutions

- Slot Recovery Solutions

- Flange Management & Bolt Tightening Solutions

- Heat Exchanger Repair

- Down Hole Rental tools

- Habitat System Isolation Chamber

- Clamp Repair Solutions

- Hot Tapping And Milling Solutions

- Orbital Milling Machine

- Poss Auto. Casing Circulating Packer

- Welding Services & Steel Fabrication

- Internal / External Cutting Solutions

Why Choose Us

- Professional Team

- Great Support

- Smart Work

LET’S START WORK TOGETHER

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

- +20225218219

- +20225218220

- +20225218221

- +220225218218

- +220223585840

- poss@poss.com.eg

- 193,195 Wadi Degla St., Industrial Area, Zahraa Maadi, Cairo, Egypt

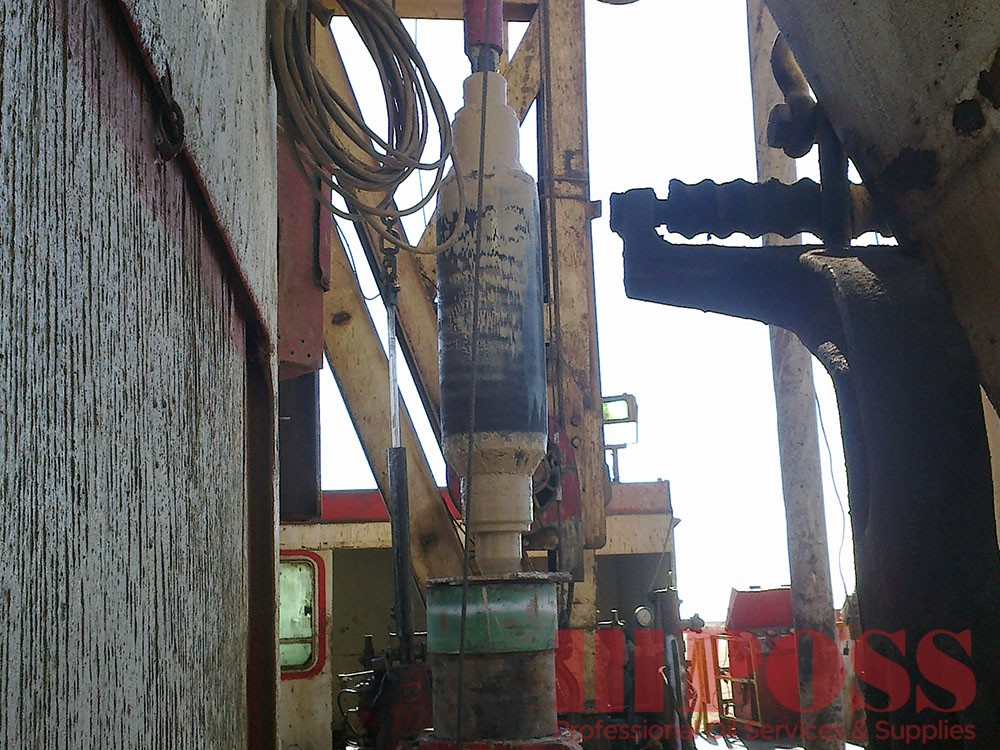

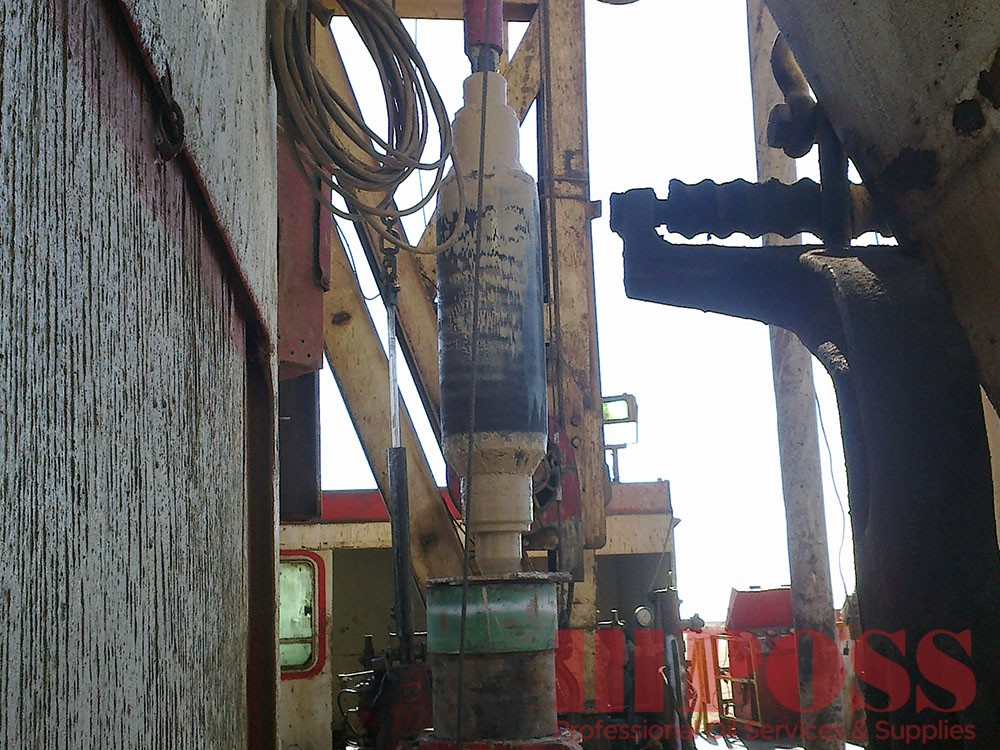

PRODUCT DESCRIPTION:

The Casing Circulator Packer (CE Tool) is used to fill casing while running in the well. It is connected to the rig’s top drive (or conventional blocks) and inserted into the casing to allow for easy filling of every joint as well as a quick and reliable means of establishing circulation when needed.

The TAM proprietary weave element design is used in the CE Tool.

For standard casing operations, the TAM CE Tool fills each joint as it is lowered into the well, cutting the fill-up time by more than half a minute per joint.

When the casing string becomes stuck, the CE Tool quickly inflates and switches to circulation mode; without having to set the slips or send a man into the derrick.

PROVIDE SOLUTIONS FOR:

– Filling casing while it is running in the well

– Circulating through the casing string with the ability to work a full-casing joint should the casing become stuck

FEATURES:

– Installs easily on all rig designs (top drive and non-top drive)

– Does not require threading to the casing

– Does not have slips. Accordingly, it doesn’t damage the casing while being used.

– Flexibility to run a range of casing sizes with various weights, thread types, and exotic materials

– Packer elements available for casing sizes 4-1/2 inch up to 30 inches. (114.3 mm to 762 mm)

BENEFITS:

– Runs as an integral part of casing operations with minimal installation

– Fills the casing while running – no separate fill-up line required

– Converts quickly to circulating mode – no need to set slips

– Internal check valve prevents mud from dripping on the rig floor

TOOL TYPE:

The CE Tool is attached to the hook on non-top drive rigs using a bail, a separate hydraulic line for the packer element’s inflation, and a side entrance port for the mud line. The hydraulic line runs from the TAM-supplied pump console to the inflatable packer element on the Casing Circulator Packer.

For top drive rigs, the CE Tool is made up to the power swivel via a 4-1/2 inch. IF connection with a separate hydraulic line to inflate the packer element. The hydraulic line runs from the TAM-supplied pump console to the inflatable packer element on the Casing Circulator Packer

(Not clear. sentences are not completed)